Encoder Coupling

This shaft coupling connects two shafts to transmit torque, motion etc. It is a coupling which can adjust itself to misalignment of two shafts connected by it. Misalignment may be angular, parallel or skew. When motion transmission is important, the misalignment should not affect the velocity & acceleration of the shaft. This calls for a torsionally rigid, yet flexible coupling. This couplings offer you this advantages using special machining processes. Given in this leaflet are various couplings used in listed applications.

FEATURES

- Aluminum alloy, St. Steel, Brass, Nylon material .

- Inbuilt flange clamping or Set screw clamping.

- Angular offset up to 5 degrees .

- Parallel offset up to 0.2mm No Backlash.

- Constant velocity transmission.

- Tortionally stiff.

- One piece construction.

APPLICATION

- Shaft Encoder .

- Tachogenerator.

- Stepper & Synchronous motor.

- Damper Drives.

- Rotary position transmitter.

OPTIONS

- Different Dia & Bore Sizes.

- Higher torsional Versions.

- Different materials.

STANDARD SIZES

| Sr.No. | Outer Dia. | d1 H7 | d2 H7 | Length | Order Code |

|---|---|---|---|---|---|

| D mm | mm | mm | L mm | ||

| 1 | 20.00 | 6.00 | 6.00 | 28.00 | AS / AF 20-6-6,L=28 |

| 2 | 25.00 | 6.00 | 6.00 | 32.00 | AS / AF 25-6-6,L=32 |

| 3 | 25.00 | 6.00 | 8.00 | 32.00 | AS / AF 25-6-8,L=32 |

| 4 | 25.00 | 6.00 | 10.00 | 32.00 | AS / AF 25-6-10,L=32 |

| 5 | 25.00 | 8.00 | 8.00 | 32.00 | AS / AF 25-8-8,L=32 |

| 6 | 25.00 | 8.00 | 10.00 | 32.00 | AS / AF 25-8-10,L=32 |

| 7 | 25.00 | 10.00 | 10.00 | 32.00 | AS / AF 25-10-10,L=32 |

Other Outer Diameter and Bore Size combitions are also available as per requirement.

TECHNICAL DETAILS

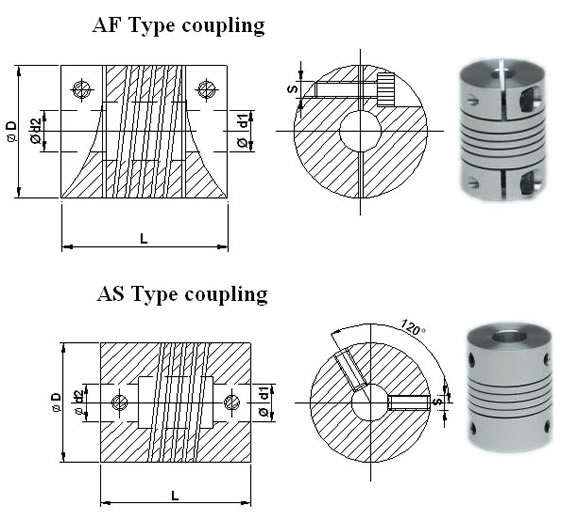

Table No.1 AF Type

| Outer Dia. | Length | d1 and d2 H7 mm | Clamping |

|---|---|---|---|

| D | L | Min.-Max. | Screw S |

| 14 | 20 | 2.00-4.00 | M2.5 |

| 16 | 24 | 3.00-6.00 | M2.5 |

| 20 | 28 | 4.00-10.00 | M3 |

| 25 | 32 | 5.00-11.00 | M3 |

| 32 | 40 | 8.00-12.00 | M4 |

| 35 | 40/50 | 10.00-17.00 | M5 |

| 40 | 50 | 11.00-20.00 | M5 |

| 50 | 50/60 | 12.00-25.00 | M6 |

Table No.2 AS Type

| Outer Dia. | Length | d1 and d2 H7 mm | Clamping |

|---|---|---|---|

| D | L | Min.-Max. | Screw S |

| 14 | 20 | 2.00-4.00 | M3 |

| 16 | 24 | 3.00-8.00 | M3 |

| 20 | 28 | 4.00-11.00 | M4 |

| 25 | 32 | 5.00-12.70 | M4 |

| 32 | 40 | 8.00-15.00 | M4 |

| 35 | 40/50 | 10.00-20.00 | M5 |

| 40 | 50 | 11.00-25.00 | M5 |

| 50 | 50/60 | 12.00-30.00 | M6 |

Technical Details

| Size O.D. mm | Rated Torque Nm | Max. Lateral mm | Shaft Axial mm | Misalignment Angular Degree | Torsional Spring Rate Ncm/rad | Clamping Screw Tightening Torque Ncm |

|---|---|---|---|---|---|---|

| 14 | 0.5 | 0.15 | 0.15 | 3 | 475 | 50 |

| 16 | 0.60 | 0.15 | 0.15 | 3 | 575 | 50 |

| 20 | 1.4 | 0.2 | 0.2 | 5 | 1250 | 100 |

| 25 | 2.5 | 0.2 | 0.2 | 5 | 1675 | 100 |

| 32 | 7 | 0.25 | 0.25 | 5 | 2000 | 200 |

| 35 | 8.5 | 0.25 | 0.25 | 5 | 2250 | 200 |

| 40 | 11 | 0.25 | 0.25 | 5 | 2500 | 400 |

| 50 | 25 | 0.25 | 0.25 | 5 | 3000 | 400 |